By Dr. Bryan Rithesh Miranda

Metals are fascinating materials known for their strength and versatility. One of their most interesting properties is malleability. But what does it mean for a metal to be malleable, and why is this property so crucial? This blog will explain why metals are malleable, explore different types of metals, and discuss their practical uses.

What is malleability?

Malleability is the ability of a material to be shaped or bent without breaking. For metals, this means they can be hammered, rolled, or pressed into thin sheets or various shapes. Think of it like dough—you can roll and shape it without it cracking.

Why Are Metals Malleable?

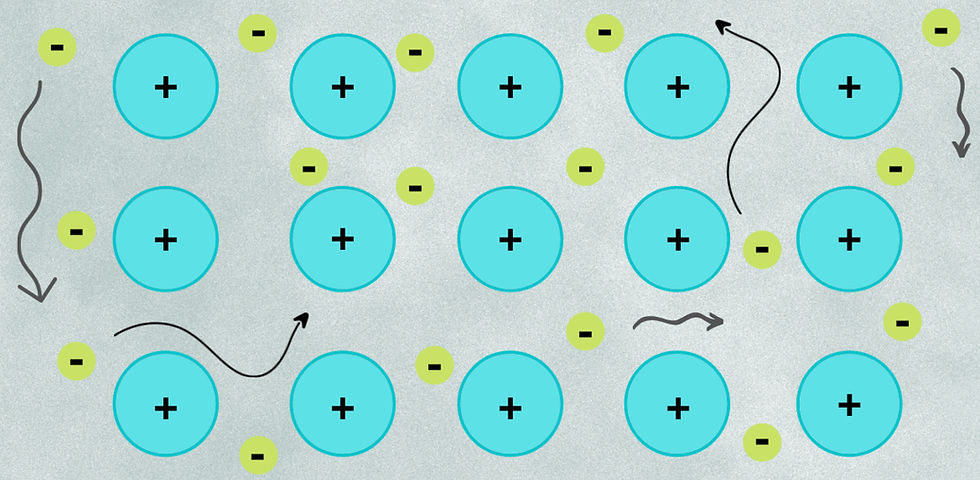

Metallic Bonding: Metals have a unique atomic structure. In metals, atoms are arranged in a regular pattern and are surrounded by a 'sea' of free-moving electrons. This arrangement allows metal atoms to slide past each other easily without breaking their bonds.

Illustration depicting metallic bonding, where a network of metal atoms shares a cloud of free-moving valence electrons, forming a structured layer. Layered Structure: The layers of atoms in metals can move over each other while keeping the metal intact. This sliding ability is what allows metals to be shaped or stretched.

Temperature Effects: Metals become more malleable when heated. Heat gives the atoms more energy, making it easier for them to slide past one another. This is why metals are often heated before being shaped in manufacturing processes.

Types of Malleable Metals

Aluminium: Known for its lightweight and resistance to corrosion, aluminium is used in everything from aeroplanes to kitchen foil. Its malleability allows it to be easily shaped into various forms.

Copper: Copper is a highly malleable metal used in electrical wiring and plumbing. It’s excellent for these applications because it can be drawn into thin wires or formed into different shapes.

Gold: Gold is one of the most malleable metals. A single ounce of gold can be stretched into a sheet covering over 9 square meters. This property makes gold ideal for fine jewellery and decorative items.

Iron: Iron is another malleable metal, especially when alloyed with carbon to make steel. This combination is used in construction, tools, and machinery.

Practical Uses of Malleable Metals

Construction:

A construction site features towering cranes and scaffolding. Malleable metals like steel are essential in building structures like bridges and skyscrapers. Their ability to be shaped into beams and reinforcements makes them invaluable in construction.

Electronics:

Close-up of a technician soldering components on a printed circuit board (PCB), highlighting the intricate pathways made of metals like copper. Copper’s malleability and conductivity make it the top choice for electrical wiring. It can be drawn into fine wires and used to connect components in electronic devices.

Packaging:

Aluminium is used to create thin, lightweight packaging materials. Its malleability allows it to be formed into cans, foil, and other packaging products.

Art and Jewellery:

Exquisite jewellery crafted from precious metals like gold and silver, adorned with shimmering diamonds and intricate designs. Gold, silver, and platinum’s malleability allows artists and jewellers to create intricate designs and fine details. These metals can be shaped into delicate patterns and custom jewellery pieces.

Metals are malleable because of their unique atomic structure and the way their atoms move relative to one another. This property is incredibly useful and is why metals are so versatile in various applications, from construction to electronics and art.

Comments